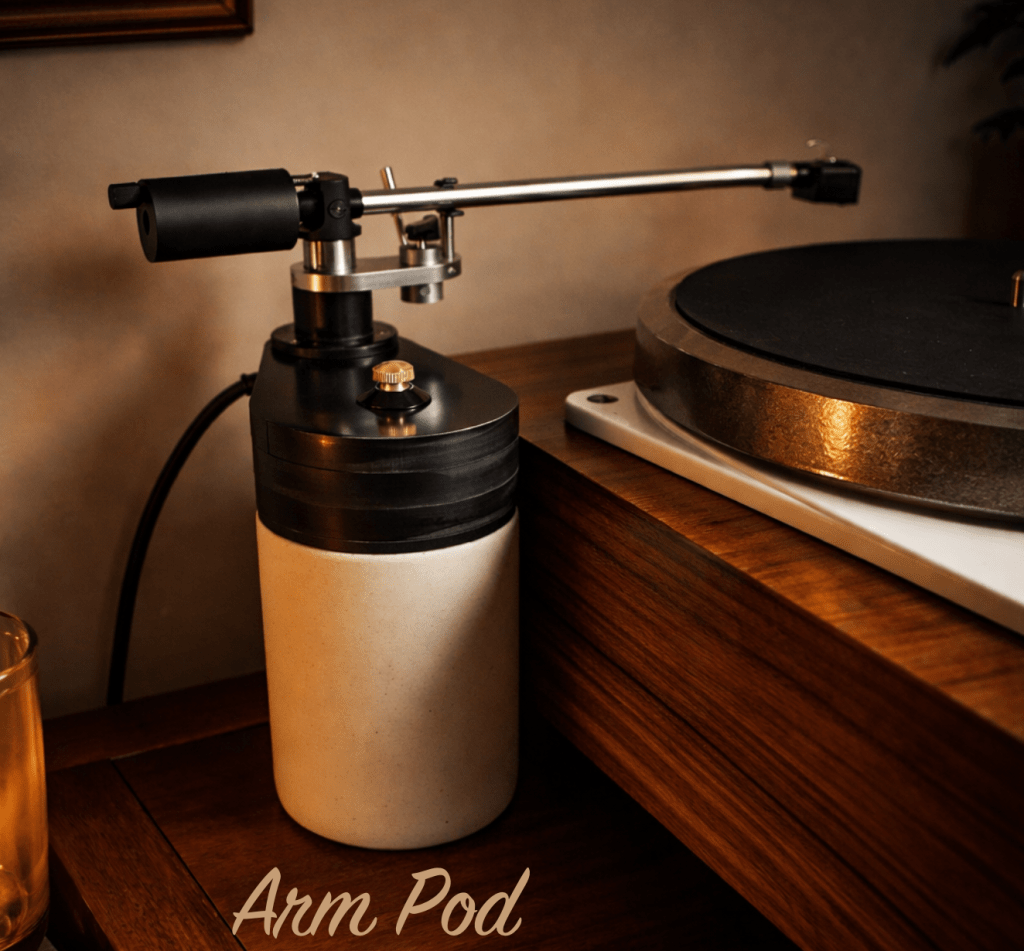

Corian / Ceramic Composite Arm Pod

There are plenty of aftermarket armpod and arm-mount solutions available, but most of them are either extremely expensive, built around someone else’s design priorities, or visually not what I wanted for this turntable. The goal here was to make something that fit my own ideas about mass, damping and mechanical behaviour, while also suiting the overall aesthetic, so this became a DIY engineering exercise rather than a shopping decision.

The armboard itself is built from four machined pieces of 12 mm black Corian, stacked to form a 48 mm thick structure. In this thickness Corian behaves as a dense, well-damped engineering material with very little tendency to ring. The aim here is simple: mass, stability, and controlled energy dissipation rather than relying on a single material to “sound right”. A friend machined the Corian on his CNC machine, and it has resulted in an excellent high precision fabrication.

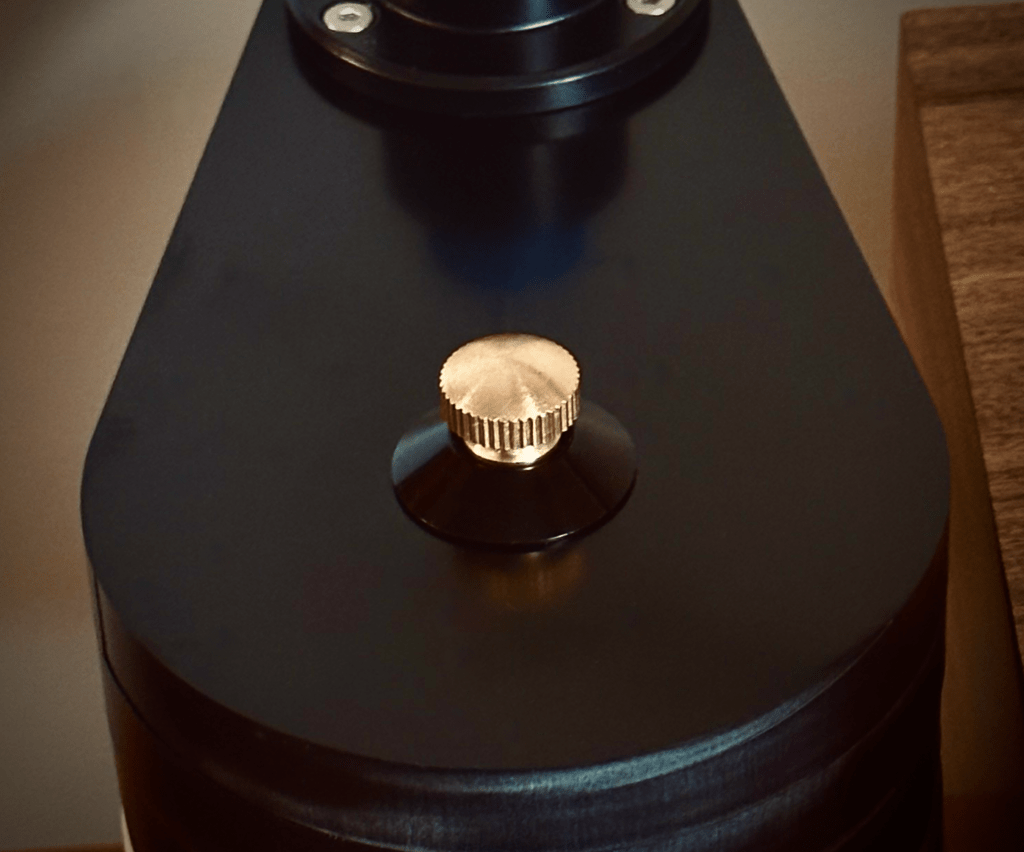

The layers are mechanically coupled using a threaded insert bonded into the lower section with JB Weld. A brass knurled thumb bolt pulls the assembly into firm compression. The brass interface adds durability and clamping force, but also introduces a dissimilar material boundary, which helps disrupt vibration transmission through the structure.

That Corian stack is JB-welded into a Japanese ceramic container which acts as an outer shell. The cavity is filled with fishing sinkers and fine dry sand. The sinkers provide concentrated mass; the sand adds particle damping and reduces internal movement. The ceramic itself forms another rigid boundary layer. Together, it functions as a constrained, multi-material damping system rather than just a heavy block. It’s actually really heavy, which is obviously needed for the weighty tonearms it will be supporting. I did think about putting some sort of felt-type pads on the bottom, but concluded that it would compromise the stability too much.

The mounting collar is placed exactly at 297mm from the spindle which ensures correct alignment. I used my fancy pivot to spindle measurement contraption to do that.

The end result is extremely rigid and inert in use. Both the Ortofon and Sorane tonearms mount securely with no sense of mechanical liveliness in the structure. Subjectively this translates to lower background noise, cleaner leading edges, and better preservation of low-level detail, not from tonal shaping, but from the platform staying out of the way. Aesthetically it is much more pleasing to me than a lump of metal sitting on my rack, and equally as functional.

It’s fundamentally a mass-loaded, mechanically grounded solution designed to minimise energy storage and feedback at the arm interface.

Overall it works really well, and I consider it a good success.

You must be logged in to post a comment.